We collect basic website visitor information on this website and store it in cookies. We also utilize Google Analytics to track page view information to assist us in improving our website.

If you’re passionate about metal cutting or just keen to learn more, you’ve landed in the right place.

For over 38 years, Amber Steel has been at the forefront of metal cutting services, specializing in laser cutting, flame cutting, and plasma cutting. Our expertise has carved a niche in this cutting-edge industry, delivering precision and excellence across industrial projects big and small.

In our blog, we’ll share a mix of useful tips, innovative applications, our thoughts on sustainability in steel cutting, and more. Expect stories from the cutting floor, insights into how our processes can streamline projects across industries, and a few lessons we’ve learned along the way.

While we keep some of our trade secrets under wraps, this blog is designed to offer valuable nuggets of wisdom that you simply won't find anywhere else. Whether you’re a professional in the industry or someone fascinated by the possibilities of metal cutting, you'll find something of value here.

So, stick with us as we delve into the finer points of metal work. We’re glad to share our insights and lead discussions that matter to our industry.

How precision metal cutting propels the aerospace industry, from constructing lighter frames to enhancing aerodynamics.

The role of advanced metal cutting in automotive manufacturing, driving innovations in vehicle design and efficiency.

All about the robust and versatile process of flame cutting, ideal for tackling thicker metals with precision and ease.

Discover the art of crafting metal furniture, where cutting techniques meet design to create both functional and aesthetic pieces.

A behind-the-scenes look at the mechanics of metal cutting technologies and the science that makes them tick.

Laser cutting is where extreme precision meets efficiency, allowing for intricate designs and clean finishes.

The critical role of precise steel cutting in developing reliable and intricate medical devices.

How steel cutting supports the oil and gas industry with components that withstand extreme environments and pressures.

Known for its speed and versatility, plasma cutting slices through conductive metals with hot plasma.

Safety first! Tips and insights on maintaining a safe environment while handling powerful metal cutting equipment.

The backbone of construction, where steel fabrication and cutting technologies create frameworks that shape skylines.

Sustainability

A look at sustainability in metal cutting, focusing on practices that reduce waste and conserve energy to protect our planet.

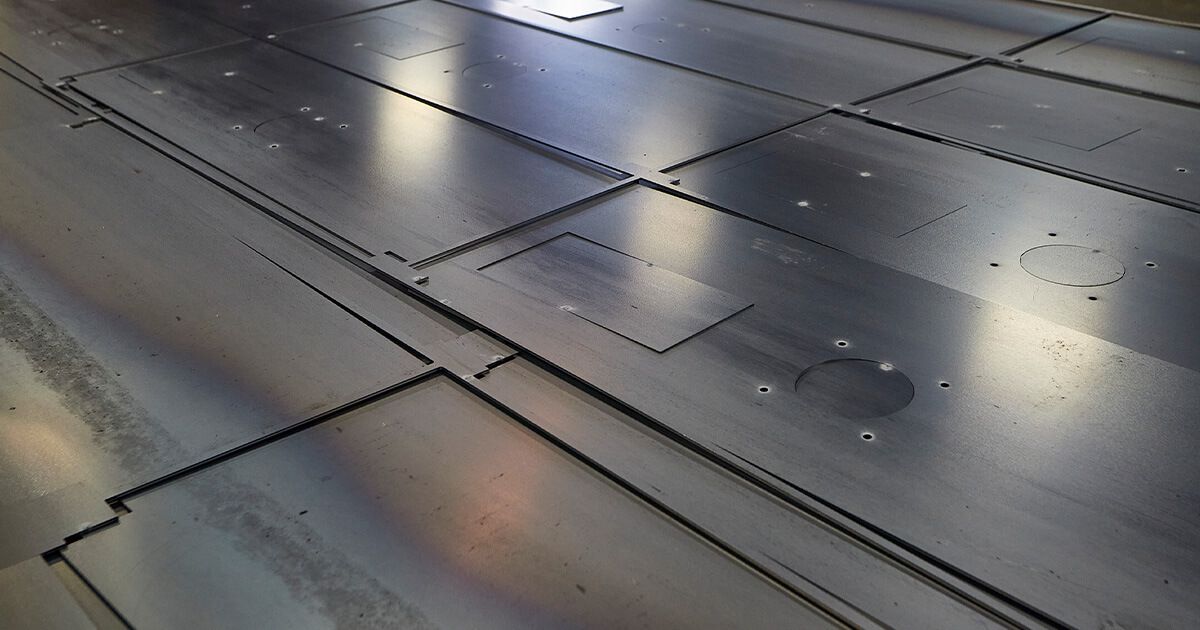

There's something truly captivating about large-scale steel fabrication.

Whether it’s the sight of flames flying during the cutting or welding process or the spawning of awe-inspiring structures that shape entire civilizations, the sheer magnitude of large-scale steel fabrication in construction is unparalleled.

Steel inspires us because of its strength, robustness, and seeming invincibility, especially when utilized at a large scale. It’s also our bread and butter as a business.

We’re not talking about steel in a shelving cabinet unit. No, this is a discussion about steel at its most jaw-dropping enormity: heavy metal for heavy machinery, shipbuilding, bridges, and construction.

In other words, big steel is a big deal. Large-scale steel fabrication is versatile and produces materials up to the task of making the world go round.

At Amber Steel, we embrace and appreciate the value of large-scale steel fabrication, utilizing techniques such as plasma cutting for precise and powerful cuts. We integrate our skill, precision, and expertise for steel fabrication with cutting-edge technologies that streamline our processes and optimize results.

From planning to executing a large-scale steel fabrication project, we apply our technical proficiency and vast industry knowledge to deliver results that exceed client expectations.

Do you have a large-scale steel fabrication project in the works? Are you seeking a top industry technician with top-tier machinery and innovative technology who can cut, bend, and assemble on a grand scale while delivering optimal results? If so, contact Amber Steel today to discuss what our steel fabrication and cutting processes can do for your business.

While we offer various techniques for steel fabrication and always have an alternative to meet your needs, we typically utilize plasma cutting for fabricating steel at a large scale.

Below, we’ll delve further into large-scale steel fabrication and the role of plasma cutting in the process.

The heavy (or large-scale) steel fabrication process applies to industrial structure/component construction from raw materials.

We already mentioned the structures built with fabricated steel: bridges, heavy machinery, and sky-scraping structures. These human-made works make people feel small and their mouths agape.

Projections show the steel fabrication industry growing from $22.36 billion in 2023 to $30.64 billion by 2030.

The above statistic isn’t a brag or boast. It’s to highlight the ubiquity and necessity of large-scale steel fabrication. Steel is everywhere—it provides stability and is the foundation for almost all industries and ways of life.

Consider the financial implications of projects that utilize large-scale steel fabrication. The average modern cruise ship, for example, can cost a mind-boggling $900 million, while a high-rise office can cost up to $1,000 per square foot. These figures emphasize the need for quality tools and experts to ensure the success and profitability of such ventures.

Furthermore, heavy steel fabrication is a staple of automotive and aerospace, both high-worth industries involving projects with immense financial stakes.

The materials used in large-scale steel fabrication reflect that massive scale, as do the final products and associated prices.

Thus, project leaders need to invest in the best tools available and ensure the top experts in the field use them. This way, the ends will justify the means, and all upfront spending will pay off.

It’s then worth asking: What are the best types of tools or machinery for large-scale steel fabrication? Several will be required, but our plasma cutter is Amber Steel's most integral tool for these projects.

Cutting is one of the first components of steel fabrication, occurring before forming, drilling/punching, welding, and blasting/painting.

Steel must first be cut to form its desired shape.

Many cutting processes exist, and Amber offers several of them, including laser cutting and flame cutting.

However, plasma cutting proves itself time and again the far superior choice for large-scale steel fabrication projects.

Specifically, plasma is the cutting method that is most efficient at handling thicker materials.

The electrically charged air in plasma cutting makes it ideal for processing nonferrous and ferrous materials. Alternatively, flame cutting can only cut ferrous materials.

Furthermore, plasma cutting works faster than oxyfuel with its cutting speed. Plus, its kerf is more precise and smaller than flame cutting.

Plasma cutting flourishes when processing high-thickness plates (e.g., approximately 2 inches or 50 mm thick). It can even succeed in handling 150 mm (6 inches) thick materials. Thus, it’s ideal for heavy, large-scale steel fabrication.

At the end of the day, our reasoning is simple: We opt for plasma cutting for large-scale steel fabrication because it’s most suited to the type of work required, offering optimal cuts in these scenarios.

We’ll note that—within reason—Amber is precisely what our clients need us to be. Thus, our services will shape and mould whatever your project and desired outcomes demand.

Still, we can give you a general idea of what to expect when you hire us for a large-scale steel fabrication project.

Read on as we break down some typical elements of the large-scale steel fabrication process with Amber.

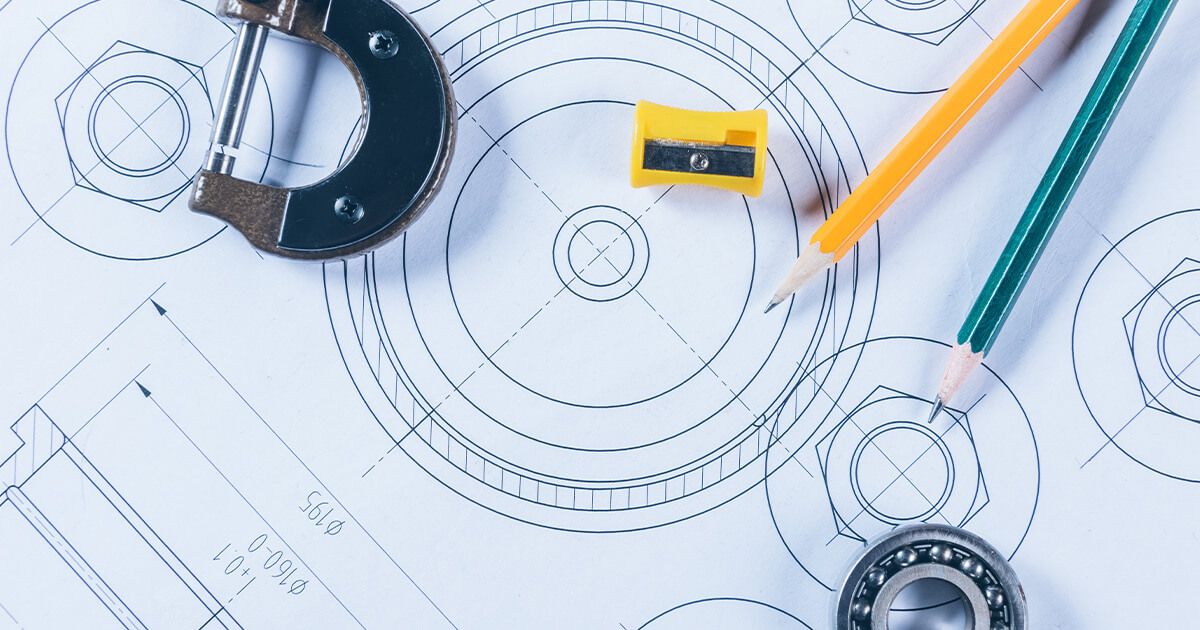

Rigorous planning is the cornerstone of any successful large-scale steel fabrication project.

At Amber, we excel and relish the planning stage because it allows us to familiarize ourselves with customers and their project specs. We combine our philosophies with our client's needs and help create budgets, schedules, and a final product blueprint.

Our detailed planning process ensures we finish projects on budget and on time.

To the above point, punctuality is one of our core tenets at Amber Steel.

Our passion and dedication to delivering on time reflect our desire and commitment to helping you succeed. We will work tirelessly during the planning stage to ensure we meet deadlines which are non-negotiable for us.

Still, even the best-laid plans can fall victim to unforeseen circumstances.

As such, we build our plans with flexibility and adaptability in mind. We prepare in advance with the idea that your needs will evolve. We have processes in place to ensure we adjust seamlessly, continuing to shape our solutions to your objectives.

We consider all large-scale steel fabrication processes as we plan your project. Say you’re building a bridge, for instance. We’ll consider the types of vehicles going over the bridge, factoring their weight into the materials we select for the project.

The most precise, beautifully cut piece of steel means very little if the client doesn’t want it.

Thus, Amber prioritizes familiarizing ourselves with your large-scale steel fabrication requirements before we plasma-cut a single material.

Here are some of the requirements we refer to:

The structure’s purposes.

It’s load-bearing capacity.

Environmental conditions

When we understand your needs, we can deliver the structures and final product that meets and exceeds expectations.

Our team of top-tier professionals might be proficient at plasma cutting. However, they’re equally skillful as communicators and utilize these skills with our clients.

We’ll share our developed designs with you for approval. This way, you can give us feedback, which we’ll enthusiastically receive during each stage of your large-scale steel fabrication project.

Large-scale steel fabrication is an intensive process saved for projects that often feature high difficulty.

Often, companies in our sector will perform a SWOT analysis to assess whether they can give prospective clients what they need for their projects. Specifically, these are the questions asked:

Do we have the resources available to finish the project?

Does our expertise and experience align with what’s needed to fabricate the structure in question?

Where are our core competencies?

How do our current finances line up with the needs of a fabrication project?

There’s rarely a project we won’t take on. Nevertheless, transparency with clients is vital to us at Amber. We want to be honest through all project facets, which means asking ourselves if we’re up to the challenge and giving clients a straightforward answer.

Suppose we find a gap or a weakness that may prevent us from working on a large-scale project. We'll investigate solutions and ways to bridge the gap, typically leading to top-tier work and happy clients.

Do you have a large-scale steel fabrication project in your sights?

Given the financial investment it requires, such work has a slim margin for error. You owe it to yourself and your fellow colleagues, partners, or investors to only work with the industry's best fabricators.

Speaking of the industry’s best large-scale steel fabricators, Amber Steel provides plasma-cutting services for heavy-duty projects that demand a sure hand.

We work with other materials, but steel is our bread and butter. Our work is highly efficient, rigorously planned, exactly precise, and guided by cutting-edge technology to ensure optimal results.

Amber Steel has spent years differentiating itself with top-quality products and competitive pricing.

Contact Amber today to learn about the game-changing difference our plasma-cutting services can make for your large-scale steel fabrication project.

As dawn breaks, the factory springs to life. A raw, unassuming sheet of steel lies on the shop floor. It will soon undergo a remarkable transformation.

The day’s work is to create a complex engine cover, a piece vital for protecting sensitive machinery. The operator uploads a CAD file, a digital blueprint detailing the intricate design. With a hum that fills the air with anticipation, the laser cutter springs into action. Sparks fly as the laser, its beam slices through the steel with surgical precision.

Within minutes, what was once a featureless steel sheet is now a perfectly shaped, smooth-edged engine cover, ready for the next stages of fabrication.

It’s an example of the marvel of modern manufacturing—a piece that began as an idea, transformed into reality by the precision of laser cutting and the skilled hands of operators.

This transformation, from raw materials to essential components, is repeated countless times across the industry every hour of every day.

In this article, we’re looking at the world of industrial laser cutting for sheet metal fabrication, exploring how this technology offers many advantages over traditional methods—focusing on its speed, cost-effectiveness, and material utilization.

If you’re interested in learning more about steel cutting or have a project in mind, reach out to Amber Steel. We’re always one email or phone call away.

Through cutting, forming, joining, and finishing, sheet metal fabrication offers limitless possibilities for creating everything from everyday items to specialized industrial components.

The first step in sheet metal fabrication is cutting, where the metal is shaped into the initial outline needed for further processing. And that’s where Amber Steel comes in:

A sheet of metal is placed on the cutting table inside the laser cutter. This table is grid or slat-based to allow the laser and any molten material to pass through without damaging the machine.

The specifications for the cut are programmed into the machine’s control system. This includes the shape, dimensions, and cutting path based on digital designs, usually provided in CAD files.

The laser beam is focused to a fine point at the cutting head, which concentrates the laser’s energy on a very small area of the metal, heating it up extremely quickly and melting or vaporizing it. The cutting head moves over the metal sheet along the programmed path.

For thicker sheets or more complex cuts, the laser may make several passes to ensure clean cuts through the material.

Once the cutting is complete, the finished pieces are removed from the sheet. The skeleton of the unused metal is also removed from the cutting table.

Laser cutting uses a highly focused laser beam to melt and cut the metal, offering remarkable precision. Because of its accuracy and smooth finish, laser cutting is ideal for detailed or intricate cuts.

To learn more about the basics of the laser cutting process, check out our post on Industrial Laser Cutting vs. Traditional Cutting Methods.

After being cut to size, the metal is shaped into the specified form. Depending on the components involved, the forming stage may involve a combination of bending, stamping, and/or rolling.

Bending: Creating angles and curves by manipulating metal sheets with mechanical force. Bending is done with various tools and machines, including press brakes, which press down on the metal to bend it at the desired angle.

Stamping: Stamping uses dies and high pressure to shape or cut the metal into a specific form. This process is used for high-volume production where the same shape is needed many, many times over.

Rolling: Metal sheets are passed through rollers that gradually form them into curved shapes or cylinders. Rolling is essential for creating components like tubes, tanks, and other rounded metal items.

After forming, the pieces must be joined to create more complex structures or final products. Welding is the most common method of joining metal pieces. Riveting, which is less common, does not involve melting but rather uses metal pins (rivets) to join two pieces of metal mechanically. It's a strong, durable joining method that doesn't affect the metal's integrity with heat.

Adhesive bonding using a strong glue, or other adhesives is a third option. It's useful for joining dissimilar metals, or where heat might damage the components (and riveting isn’t an option.)

The final step in sheet metal fabrication is finishing. This can include sandblasting to provide a textured finish that adheres well, painting, or plating with chrome or zinc.

Laser cutting is the go-to choice for sheet metal fabrication, especially in precision-driven industries like automotive and aerospace.

Laser cutting speeds up the production process significantly. This machine is fast when it comes to cutting, and it also reduces setup times. With laser cutting machines, switching between different designs is a breeze. There’s no need to swap out physical tools or dies, which means we can go from one design to another in no time.

One of the biggest advantages of laser cutting is its precision. The laser can achieve cuts and details so fine that other methods simply can't match. This high level of accuracy ensures that parts fit perfectly in subsequent assembly stages, reducing or even eliminating the need for further machining. That means faster production from start to finish.

Laser cutting is incredibly efficient in terms of material use. The laser beam is so precise that it minimizes excess cut, maximizing the number of parts that can be created from a single sheet.

Thanks to laser cutting's automation capabilities, fewer hands are needed on deck. This helps reduce costs and minimizes human errors, leading to a smoother, more efficient production line.

Plasma cutting is also a viable option for sheet metal fabrication. In general, it is a cheaper and easier process than laser cutting, and can be carried out with a handheld device. To learn more about plasma cutting, read our post on How Plasma Cutting Works & Its Advantages.

Sheet metal fabrication involves a lot of steps, from cutting all the way to finishing. You might wonder why we choose to specialize exclusively in laser cutting instead of handling the entire process.

There are good reasons for that:

We pour all our efforts and resources into the cutting process, a specialization that leads to unmatched efficiency and quality. By concentrating solely on cutting, we've invested in the latest technologies and attracted skilled operators who are serious about their craft. This means that when you trust us with your cutting needs, you're benefiting from top-tier expertise that's hard to find elsewhere.

Specialization allows us to work more efficiently, which translates into lower costs for you. We can achieve economies of scale, optimize our resource use, and maintain lower overhead costs than companies that try to cover every stage of fabrication.

Outsourcing laser cutting allows you to scale up or down production without adjusting your workforce or investing in new equipment. Our operation is designed to adapt quickly and efficiently, meeting your needs, whether they spike unexpectedly or grow over time.

Our approach not only ensures excellence in the parts we produce but also supports the overall success of your projects by allowing you to focus on your core competencies while leaving the intricate cutting details to us.

At Amber Steel, our 72-inch wide laser cutter means we can handle larger sheets of metal than most. We’re not stuck on standard sizes. It’s great for making big parts or getting the most out of each sheet.

And as discussed, our focus on specialized laser cutting means we deliver high-quality parts efficiently and effectively. We’re here to provide the precise cuts and quick turnaround times that our clients depend on. Amber Steel is more than equipped to support your projects and keep things moving smoothly.

So, if you’re looking for a reliable partner in the steel fabrication industry, consider how Amber Steel can help you achieve more with your projects. Whether you need large-scale production or specific custom parts, we’re equipped to deliver exactly what you need.

Learn more about steel cutting by contacting us today. Or, reach out with an email or phone call if you have a project in mind and wish to discuss it with industry experts.